Creating sustainable, transparent and traceable supply chains

With supply chains making up a majority of many companies sustainability impacts (from carbon to biodiversity and labour rights), effectively managing supply chain approaches and partners is an essential element of delivering against the just transition. This is therefore becoming an increasing focus for companies covering a number of key topics in order to drive sustainability (and transparency and traceability) in the supply chain with a focus on two areas:

Product Specific

-

Scope 3 emissions – and overall carbon intensity

-

Water use and water quality (e.g. management of waste water)

-

Nature of production – Organic, regenerative, etc.

-

Waste management (from production efficiency and use of waste materials to pollutants)

-

Plastics (single use, circularity approach, packaging, etc.)

-

Product composition (designed for circularity through to materials substitution)

People/Planet Specific

-

Biodiversity - impact on the planet of operations

-

Deforestation - part of biodiversity, but specific issue in areas such as food/natural products

-

Forced labour - in all its forms

-

Child labour - use of child labour in any element of production

-

Minimum/living wage - provision of a living wage to all employees

-

Diversity & Inclusion

-

Land rights - prevention of land right loss

Tools provided: Supply Chain sustainability strategy review toolkit:

At the Chestnut tree partnership we apply a five stage process in order to target and manage these issues:

Stage 1: Development of the strategy

-

Understand supply chain impacts on corporate sustainability delivery (using existing metrics where available)

-

Identifying key drivers of sustainable supply chain development – from regulation through product development to sustainability positioning

-

Determine the sustainable supply chain development path looking at use cases and how to drive incremental value through the build process (i.e. internal cost reduction from reduction of manual/repetitive activity through to optimising supply chain delivery)

Stage 2: Focus on internal processes/systems

-

Review of current systems/data bases to detail current approach/impacts

-

‘Leaky pipe’ analysis of existing process to determine key gaps and inefficiencies (including determining key hand offs, SLAs, skills needed, etc.)

-

Data review – determine where data is held, accessibility and quality of the data for link into the broader process (includes internal/partner and licensed/purchased data)

-

Build ‘To-be’ process in order to optimize for current and future sustainability requirements – and implement – will include everything from governance/metrics, through organisation design and product redesign

Stage 3: Creating supply chain transparency

-

Determine approach (staging) for supplier base – e.g. 80/20 from a value or volume basis.

-

Look into redesign supply chain process to building in efficiency/sustainability/data

-

Build out initial elements of the Supply Chain with detailed trace/data ingestion

-

On-boarding of suppliers – starting with Tier 1 and then trace back

-

Use to create full transparency map for business and start change journey for suppliers

-

Leverage AI/Gen AI tools to develop mapping of unstructured data (e.g. child labour)

Stage 4: Data overlay/insights/

-

Determine use cases to pursue supply chain optimisation – order and value created

-

Determine external data needs to support use cases and availability

-

Develop solutions – from support businesses through their drive for sustainability to leveraging procurement approaches to signal intent

Stage 5: Link into core procurement

-

Determine data quality requirements to support buying approach

-

Map data feeds, review quality/comparability, refresh rates etc.

-

Build out decision criteria for how to trade off price, volume, sustainability, etc.

-

Build into procurement decision support tool – including scenario development approaches to test options

-

Determine how to incorporate into core elements of supply chain chain delivery - from supply chain optimisation to balancing

-

Determine how to drive optimisation in the supply chain (from supplier 'swapping' to supporting suppliers in their sustainability journey)

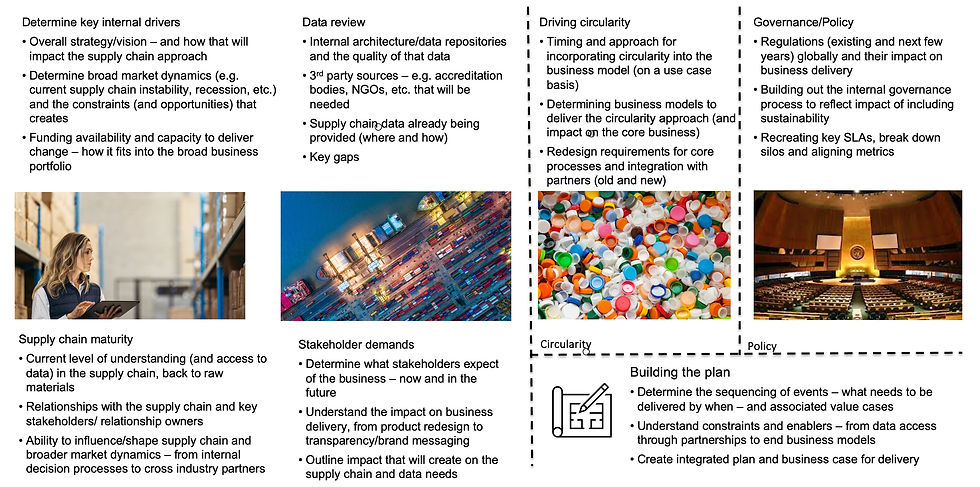

An outline of the elements to define in building out this journey is highlighted in the diagram below:

Examples of work delivered

Supporting businesses to move from transparency/trace to building carbon into purchasing and developing the supply chain options for full circularity